The Once Over…Xray T3

Team Xray have one of the most relentless development programmes for their cars in the RC industry. The Slovakian manufacturer has made massive inroads into the racing marketplace through this with a range that encompasses most on-road classes and nitro off-road too. It is electric on-road 1:10 touring cars though where they mainly built their brand and gained the reputation for high quality, high perfomance products and here we have a look at their latest chassis in this class, the T3.

Although the T3 looks similar to the previous chassis, there are a whole host of detail changes aimed at totally optimising the car. The main developments here centre on the positioning of parts and the drivetrain to allow for the best possible weight balance for LiPo batteries and brushless electrics. Also the T3 comes with the machined aluminium parts anodised in orange.

The rear bulkheads are two piece items on either side to allow the chassis more flex in these areas.

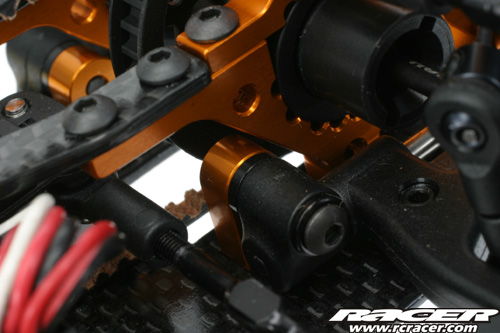

The T3 comes to you with larger differential pullies, as per the original T2 ‘008. This means that new drive belts are also used for the front and rear.

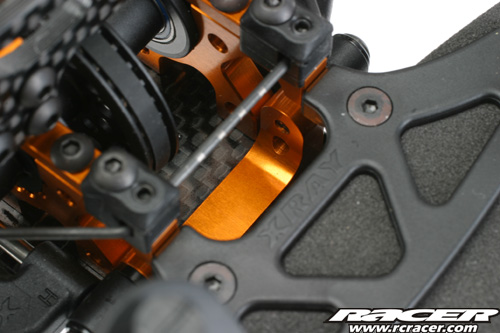

The method of mounting the wishbones has also changed on the T3. Instead of hanging them at their inboard end via plastic hinge pin holders off the main transmission bulkheads, these plastic mounts now affix to separate alloy mounts that are screwed to the main chassis plate.

The front inboard mount for the pivot blocks is shown here under the kit included anti-roll bar.

Adjustment of Ackermann rate is done via this screw in the steering bellcrank.

The weight of the CVD driveshafts has been pared down to the bare minimum.

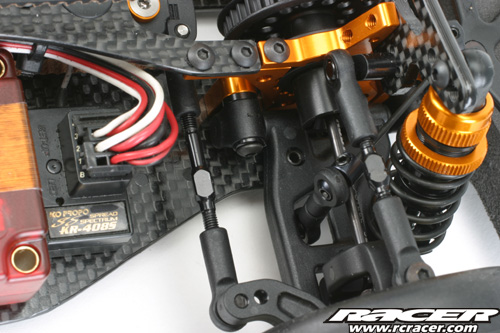

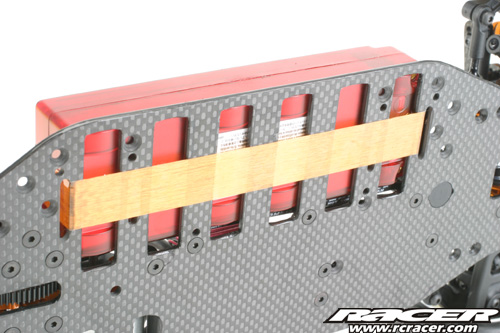

The shot above shows best how Xray have re-balanced the weight in the new T3. The cells have been moved outwards as LiPo packs are lighter than NiMh cells and the electrics have been given more space so they can move more towards the chassis’ centreline. This change has led to the drivetrain being re-engineered with the main belt and front differential now being offset from the chassis centre.

Xray’s high quality shocks remain with plenty of adjustment available on the carbon shock tower.

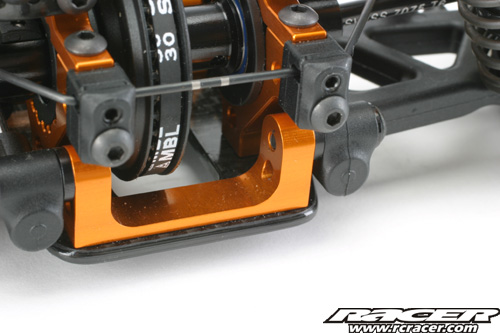

A view of the alloy rear mounting for the inner hinge pin blocks. Both front and rear anti-roll bars are kit stock.

Camber link positions and siting have also been changed to go give a longer link.

A new design top deck also comes on the T3. This comes from a long way back on the rear bulkheads…

…all the way to the front end. The top deck is now also mounted higher to clear LiPo packs.

Our T3 is the EU Edition and has cell slots cut in the chassis to accept six-cell NiMh packs too.

The rear wishbones now have additional anti-roll bar mounting balls moulded in.

The front end showing the offset drive belt on the front axle.

So there you have a brief look at our Xray T3. Is it a significant improvement over the previous car which in itself was very good? Read our full Thrash Test review in the forthcoming April 2010 issue of Racer Magazine where our Xray touring car expert, Luke Burley will give you the lowdown.

For further information and your local stockist in the UK, visit UK distributor RC Disco’s website by CLICKING HERE

For international inquiries, check Team Xray’s website by CLICKING HERE