How To Mount A Fuel Tank

A fuel tank on a nitro powered RC car can affect the performance dramatically, which in competition, can easily affect the result. Nearly all of the nitro kits we test at Racer rely on the engine being fed fuel from the tank under pressure. The pressure feed relies on back-pressure, which is why there is a piece of fuel pipe linked off the exhaust. This then pressurises the tank and pushes fuel through the tank and up to the carburettor. Although an engine does effectively suck the fuel through due to its two-stroke action, some engine tuners can set their engines to rely on just the suck so the tank is not pressurised. But the most common arrangement is to utilise the reliability of a pressurised set up.

Parts Guide

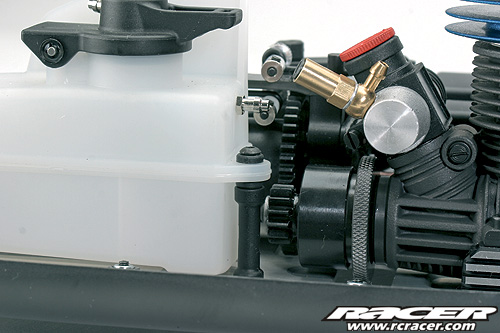

The main components of any fuel tank are the basic tank with a flip top lid, fittings for the pressure pipe to the exhaust and fuel outlet, as well as baffles inside and a brass fuel filter at the lowest point. These tanks range in sizes from around 60cc through to 175cc depending upon the size of kit and application. Monster trucks often feature the biggest of tanks as the larger the capacity, the greater run time and therefore, more fun. On other types of car like 1:10 nitro touring car of 1:8 rallycross, the organisations around the world stipulate a limit on capacity to try and retain a level playing filed. As result, fuel tank capacity I regularly checked at the race tracks to ensure the rules are adhered to.

But a fuel tank needs to be correctly installed and working well no matter whether you are a street pounder, racing in competitions or just want to have fun. So we will look at all of the areas and identify the potential problems and how to overcome them easily.

Mounting

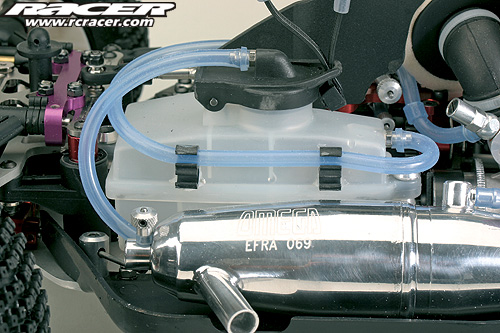

When you drive around, the fuel inside the tank sloshes around and can foam up which can affect its delivery to the engine. This is one reason why the manufacturers incorporate mouldings in the tank or baffles, to try and limit the movement of the fuel, which leads to foaming. Although this cannot be changed, it is worth allowing your fuel tank to wobble a little. You can do this in a number of ways. Firstly, make sure that the two mounting screws are not tightened right down on the tank. Back these off half a turn and this should allow a little side-to-side movement. If the mounting screws are a tight fit though the holes, then you will need to make these a little bigger first of all. You can also use grommets through the holes or a little fuel tubing to cushion the movement. To fit a grommet, you will need to make the mounting holes bigger but be careful, as there is not a lot of spare material around the holes to start with.

Flip Top Lids

We have had many instances here at Racer where the lid doesn’t shut tight on the tank and this creates an air leak. Sometimes you will have to push the lid down for it to close and this is often due to some imperfections in the design or fitting. It may be necessary to trim the lid or the tank, as this is often where the problem arises. Use a sharp knife to carry this out but make sure that none of the cut away material falls into the tank. If it does, you will need to flush it out. After this, the tank lid should close quickly and easily. There should be no binding between the tank and lid and you should not be able to push the lid down any further once shut.

Finally, make sure that the body around the tank is not interfering with the operation of the flip top lid. There may be instances where the lexan restricts the closure and so remove some of the offending material so that the action is a clean snap shut one.

Fuel Pipe

The fuel pipe is naturally an integral part of any fuel tank as it connects the fuel tank to the carburettor and acts as feed for the fuel tank that from the exhaust to create a pressurised system. Fuel foaming is something to try and avoid and a lot of people will use a longer pressure pipe that reduces the pressure to the tank and should offer a more consistent feed. Alternatively, some of the manufacturers like Mugen and Kyosho sell a special pressure fitting that looks like a fuel filter but does in fact sit in the pressure line. This too helps to prevent surges and keep a more consistent pressure to the tank.

Finally, make sure that the fuel pipe is kept well away from the flywheel and other rotating parts. Any nick, split or hole in the fuel line or pressure pipe will create havoc with your engine, as this will affect the pressure and the flow of fuel. As a result, your engine can cut, the idle can go up and down (hunt) and the performance will be erratic. If you suffer from these, then there is a good chance that you have some form of air leak and that is one of any engines worst nightmares. There are many clips available that can allow you to position the fuel pipe out of the way and this costs just a few pounds and a little of your time.

As we always state with nitro engine powered cars and buggies, preparation is the key to reliability and getting the most amount of fun with your RC vehicle.